About Us

Classic Elegance LLC, established in 2013, is a family-owned furniture wholesaler nestled in the northwest corner of Wilmington, Delaware. An idea initially intended to create high quality, leather-centric furniture for our own home has blossomed into a purposeful and passionate small business dedicated to creating and/or restoring high quality, sophisticated, classically-styled furnishings for both home and office.

What follows are some thoughts, philosophy, and facts regarding this furniture journey we have undertaken. We hope you enjoy learning about us, our approach and a little bit about furniture through these topics, but more importantly, by experiencing the practical result in our classically elegant furniture.

Classic Elegance LLC, established in 2013, is a family-owned furniture wholesaler nestled in the northwest corner of Wilmington, Delaware. An idea initially intended to create high quality, leather-centric furniture for our own home has blossomed into a purposeful and passionate small business dedicated to creating and/or restoring high quality, sophisticated, classically-styled furnishings for both home and office.

What follows are some thoughts, philosophy, and facts regarding this furniture journey we have undertaken. We hope you enjoy learning about us, our approach and a little bit about furniture through these topics, but more importantly, by experiencing the practical result in our classically elegant furniture.

Craftsmanship

Throughout this narrative, we have used the word craftsmanship when describing our work. Why do we say "craftsmanship?” Because the word embodies quality, tradition, artistry, skill and attention to detail, words representative of our value system, the way we think about our craft, the way we passionately approach every single piece of furniture that moves through our doors. These are not terms found in modern day mass production, where speed and efficiency are more important than quality, where numbers are more important than "just right." Every piece we restore or create is done so by hand and is unique in some way, deserving of the attention we believe you will ultimately see and appreciate in the final product. The techniques and methods we employ from joinery to finishing to gilding are traditional, passed down for generations, and have evolved through centuries of refinement in the trade. We put our “craft” along with our values into practice every day at Classic Elegance, LLC.

Throughout this narrative, we have used the word craftsmanship when describing our work. Why do we say "craftsmanship?” Because the word embodies quality, tradition, artistry, skill and attention to detail, words representative of our value system, the way we think about our craft, the way we passionately approach every single piece of furniture that moves through our doors. These are not terms found in modern day mass production, where speed and efficiency are more important than quality, where numbers are more important than "just right." Every piece we restore or create is done so by hand and is unique in some way, deserving of the attention we believe you will ultimately see and appreciate in the final product. The techniques and methods we employ from joinery to finishing to gilding are traditional, passed down for generations, and have evolved through centuries of refinement in the trade. We put our “craft” along with our values into practice every day at Classic Elegance, LLC.

Thoughts on “Antique”

We all love old furniture and antiques, but what is the difference between plain old furniture and an antique? Antique classification / restoration is still a highly controversial topic. Amongst antique professionals, the debate is ongoing. The concept of value beyond function now occupies the reality of contemporary living. We believe that, depending on the piece, some authentically historic antique pieces should more properly reside in museums, be obtained by collectors and enthusiasts, or be studied by scholars and other experts. Therefore, restoration of extremely valuable, sometimes priceless objects should more appropriately be left to the historians and antique professionals. We restore “non-museum” antiques to give them a new and purposeful life for their owner’s enjoyment. Since antiques live or die by subjective rules and restorations, it is really up to each individual to determine what antique furniture is, and how its true value may be derived. Naturally, the usual purpose of furniture restoration is to return the original appearance and/or functionality of the object piece. The functionality of an item could be achieved simply by cleaning, then repairing it. This approach is trending in furniture boutiques whose sales pitches imply that a pieces’ worn look imputes value to it. But, restoring an item to display its beauty and functionality for generations, as it was originally intended is, in our opinion, akin to creating a work of art. Depending on the motives for restoration, for either historical preservation or returning functionality and appearance, sacrifices have to be made for one or the other. For example, stripping will completely deflate a piece’s historic value, and the original patina which is valued by many will be lost. However, the new finish will provide value through durable protection, returning the original appearance, and emphasizing the natural beauty of the underlying wood and original joinery.

We all love old furniture and antiques, but what is the difference between plain old furniture and an antique? Antique classification / restoration is still a highly controversial topic. Amongst antique professionals, the debate is ongoing. The concept of value beyond function now occupies the reality of contemporary living. We believe that, depending on the piece, some authentically historic antique pieces should more properly reside in museums, be obtained by collectors and enthusiasts, or be studied by scholars and other experts. Therefore, restoration of extremely valuable, sometimes priceless objects should more appropriately be left to the historians and antique professionals. We restore “non-museum” antiques to give them a new and purposeful life for their owner’s enjoyment. Since antiques live or die by subjective rules and restorations, it is really up to each individual to determine what antique furniture is, and how its true value may be derived. Naturally, the usual purpose of furniture restoration is to return the original appearance and/or functionality of the object piece. The functionality of an item could be achieved simply by cleaning, then repairing it. This approach is trending in furniture boutiques whose sales pitches imply that a pieces’ worn look imputes value to it. But, restoring an item to display its beauty and functionality for generations, as it was originally intended is, in our opinion, akin to creating a work of art. Depending on the motives for restoration, for either historical preservation or returning functionality and appearance, sacrifices have to be made for one or the other. For example, stripping will completely deflate a piece’s historic value, and the original patina which is valued by many will be lost. However, the new finish will provide value through durable protection, returning the original appearance, and emphasizing the natural beauty of the underlying wood and original joinery.

An interesting and valid question: “What is the true value of an antique that is both functionally unusable but not able to be displayed? There are several factors to be considered. People with the financial resources to spend on valuable antiques may not like antiques and their diminished usability. In addition, it is unfortunately not uncommon for a dealer to offer furnishings in ‘original’ condition while the piece had actually been worked on. There are now many fakes and forgeries introduced to the marketplace, and people usually rely on their own knowledge and instincts to judge these ‘antiques’. Younger generations are less likely to have a taste for antiques or older furnishings. What is ‘antique’ and the value placed thereon are very subjective assessments, made differently by each individual. Ultimately, the practical measure of a piece’s value can be simply determined by asking: “Do you love it?” The value inherent in any piece is as unique as each of us.

As we select an antique, antique reproduction, or older furniture piece to be restored, we keep in mind a high purpose of fine furniture... to provide enduring beauty, enjoyment and functional use, able to be passed on to one’s children and grandchildren, conveying charm and a sense of history through the beauty of design and craftsmanship. In that pursuit, we apply the finest artisan skills, materials, and attention to detail to every piece we restore or create...furniture whose beauty will last generations, able to withstand the rigors of an active household.

As we select an antique, antique reproduction, or older furniture piece to be restored, we keep in mind a high purpose of fine furniture... to provide enduring beauty, enjoyment and functional use, able to be passed on to one’s children and grandchildren, conveying charm and a sense of history through the beauty of design and craftsmanship. In that pursuit, we apply the finest artisan skills, materials, and attention to detail to every piece we restore or create...furniture whose beauty will last generations, able to withstand the rigors of an active household.

Approach to Construction

In our restorations, we maintain each piece’s unique character by carefully repairing original joints with modern glues and epoxies. A great end product begins with a solid foundation, the very framework of each piece. Joinery methods have changed and improved over the centuries, but some techniques have withstood the test of time. Our craftsmen use only defect-free solid hardwoods assembled by appropriate combinations of joinery techniques. Frame joints are double-dowelled and corner-blocked. Corner blocks are glued and screwed into the frame for maximum strength and durability. Typically, the type and quality of wood chosen will greatly affect the price and construction of the furniture.

Solid wood construction is considered the highest quality for furniture. The pieces we select for restoration or original construction are made entirely of solid Cherry, Rosewood, Mahogany, Walnut, Maple, Oak or Birch, or a combination of solids and fine veneers for some outer surfaces These are the most desirable hardwoods and vary in cost based on availability and grade.

In our restorations, we maintain each piece’s unique character by carefully repairing original joints with modern glues and epoxies. A great end product begins with a solid foundation, the very framework of each piece. Joinery methods have changed and improved over the centuries, but some techniques have withstood the test of time. Our craftsmen use only defect-free solid hardwoods assembled by appropriate combinations of joinery techniques. Frame joints are double-dowelled and corner-blocked. Corner blocks are glued and screwed into the frame for maximum strength and durability. Typically, the type and quality of wood chosen will greatly affect the price and construction of the furniture.

Solid wood construction is considered the highest quality for furniture. The pieces we select for restoration or original construction are made entirely of solid Cherry, Rosewood, Mahogany, Walnut, Maple, Oak or Birch, or a combination of solids and fine veneers for some outer surfaces These are the most desirable hardwoods and vary in cost based on availability and grade.

Once we choose a high quality piece for restoration, we carefully examine the way it is constructed. Poor construction can undermine even the best solid wood. Wood joints swell and shrink together with the natural changes in humidity. “Mortise and Tenon,” “Tongue and Groove,” and “Dovetail” joints are some of the strongest joints used, and are preferred in our restorations. These tightly fitting joints increase the contact surface area of the wood and increase the strength of bonding to produce a more durable piece of furniture. Our original creations utilize these same joinery and bonding methods as well.

Classic Elegance seating (i.e sofas, love seats, ottomans, fainting couches, chairs, etc.) is usually heavier than mass-produced seating because of sturdier frames that are constructed of properly dried hardwoods, free from knots and defects. To record the quality of every piece, we take pictures during various phases of restoration to document how they are put together on the inside. For example, you would be able to see that legs are a bonded part of the frame and not just screwed on during completion. Since we use only Full Grain Leather as a covering, which can last a very long time, we naturally want to insure that the strength and dependability of our frames will have similar endurance. In all restorations, we carefully return every frame to as near new condition as possible.

Classic Elegance seating (i.e sofas, love seats, ottomans, fainting couches, chairs, etc.) is usually heavier than mass-produced seating because of sturdier frames that are constructed of properly dried hardwoods, free from knots and defects. To record the quality of every piece, we take pictures during various phases of restoration to document how they are put together on the inside. For example, you would be able to see that legs are a bonded part of the frame and not just screwed on during completion. Since we use only Full Grain Leather as a covering, which can last a very long time, we naturally want to insure that the strength and dependability of our frames will have similar endurance. In all restorations, we carefully return every frame to as near new condition as possible.

Seating

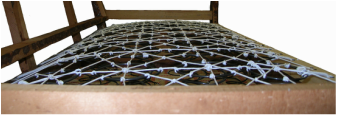

How is our seating constructed? After we complete a frame, we install traditional strip webbing, the base foundation for the internal spring system. It's tightly stretched across the frame and woven back and forth like the reed strips in a basket. We firmly attach heavy gauge coil springs to the webbing. On the underside of a true hand-tied coil system you can actually feel each spring’s attachment point. In the construction of these spring groupings, our craftsmen individually tie each coil to its neighboring coil. Each row of coils is then tied front to back, side to side, and diagonally two ways, making eight ways in all. All are slightly compressed and tied on exactly the same level to make a symmetrical, even suspension for the most comfortable seating possible. The entire system is then carefully anchored to the frame at each perimeter spring with old-world techniques that prevent premature wear and failure. Most upholsterers believe that an eight-way hand-tied spring system is the best way to create a stable, durable seat because coils connected in this manner distribute a person’s weight more evenly. The individual springs, when tied together, still have coordinated wide-ranging movement that provides a very uniform and individual "sit" because the springs move up and down and side to side in harmony. This system creates durability too, because it practically never gives out. A traditional spring installation method, it is believed to be the strongest, most resilient, flexible seating foundation possible. It also offers the advantage of longevity that is similar to a well constructed frame and quality leather coverings. Ultimately, seating with eight-way hand-tied coil systems offers the best possible foundation for comfort.

How is our seating constructed? After we complete a frame, we install traditional strip webbing, the base foundation for the internal spring system. It's tightly stretched across the frame and woven back and forth like the reed strips in a basket. We firmly attach heavy gauge coil springs to the webbing. On the underside of a true hand-tied coil system you can actually feel each spring’s attachment point. In the construction of these spring groupings, our craftsmen individually tie each coil to its neighboring coil. Each row of coils is then tied front to back, side to side, and diagonally two ways, making eight ways in all. All are slightly compressed and tied on exactly the same level to make a symmetrical, even suspension for the most comfortable seating possible. The entire system is then carefully anchored to the frame at each perimeter spring with old-world techniques that prevent premature wear and failure. Most upholsterers believe that an eight-way hand-tied spring system is the best way to create a stable, durable seat because coils connected in this manner distribute a person’s weight more evenly. The individual springs, when tied together, still have coordinated wide-ranging movement that provides a very uniform and individual "sit" because the springs move up and down and side to side in harmony. This system creates durability too, because it practically never gives out. A traditional spring installation method, it is believed to be the strongest, most resilient, flexible seating foundation possible. It also offers the advantage of longevity that is similar to a well constructed frame and quality leather coverings. Ultimately, seating with eight-way hand-tied coil systems offers the best possible foundation for comfort.

The best way to verify that you are getting a high quality hand-tied system rather than a lesser quality eight-way machine-made system is to educate yourself on the subject. Furniture stores often justify the higher cost of seating by advertising its ‘Traditional Eight-Way Tied’ construction. The traditional “by hand” method does offer superior comfort if actually hand-tied, but should never be confused with “Drop-In” and / or “Machine-Tied” coils. A drop-in machine-tied spring system is a pre-assembled, machine-made coil system connected by wire and designed to simulate the hand-tied string version. It drops into the frame and is either fastened only at the corners, or occasionally at intermediate frame locations, but not at every single spring. This type of coil system attempts to mimic the traditional method of Eight-Way Hand-Tied Coils, but is generally considered inferior in the support and comfort it offers. If you don’t feel an attachment point at the bottom of each spring, it is either a drop-in coil unit being called an 8-way system or an even lesser quality system of ‘sinuous’ (no-sag) springs. Summarizing, a true hand-tied system uses natural, flexible materials with ‘give’ to complete the coil ‘system’ yielding a seat ‘feel’ that is perceptibly more harmonious and comfortable while still highly durable.

Much like colors and shapes work together in a piece to create an overall aesthetic, the quality of a piece’s interior is equally as critical as frame construction and coverings. Since the leather we use in our upholstering can last for a very long time, and restored frames are made significantly more structurally durable, it is logical to use internal padding and protective layers that will last as long the rest of each seating piece’s components. Foam padding has continued to grow in popularity and sophistication over the last few decades as horse hair becomes less available. Although readily available as a substitute for horse hair, swine hair is much less springy and durable, permanently compressing much more quickly than horse hair. So, it is a good thing that there are several industry standard tests that manufacturers use to ensure that the modern foams they offer will be long-lasting, viable alternatives to hair.

Much like colors and shapes work together in a piece to create an overall aesthetic, the quality of a piece’s interior is equally as critical as frame construction and coverings. Since the leather we use in our upholstering can last for a very long time, and restored frames are made significantly more structurally durable, it is logical to use internal padding and protective layers that will last as long the rest of each seating piece’s components. Foam padding has continued to grow in popularity and sophistication over the last few decades as horse hair becomes less available. Although readily available as a substitute for horse hair, swine hair is much less springy and durable, permanently compressing much more quickly than horse hair. So, it is a good thing that there are several industry standard tests that manufacturers use to ensure that the modern foams they offer will be long-lasting, viable alternatives to hair.

At Classic Elegance, we use only ‘high density’ highly resilient foam because it offers the greatest degree of support and durability while still retaining its shape and original density. Foam density is a specific measurement of how much weight in pounds foam can support per cubic foot. Higher density foam will remain responsive longer, it features the perfect amount of cushioning and stiffness, and yields very comfortable and supportive seating. We also use cotton batting on the top of spring protective coverings, and then again to cover the foam layer before we install a final layer of 100% wool batting for soft texture and comfort.

For the final layer before leather coverings, a top layer of 100% wool is highly preferred for its lightness in weight, warmth, springiness and resilience. Wool is a natural insulator, it helps your body feel cozier in the winter and cooler in the summer, it can absorb moisture without feeling wet and will help keep your seating retain its comfortable feel even on very humid days. When the humidity is lower in winter, wool will release moisture into the air and help keep leather from drying. Wool fibers have microscopic scales on each strand that wick away moisture and prevent a "clammy" feel. Because its fibers are kinked, wool springs back beautifully when it's compressed. Wool will retain its comfort and insulating properties without losing its soft, luxurious feel. Wool has the ability to regulate temperature - wool fibers keep a pocket of air close to your body. The coil-shaped fibers naturally wick excess heat to create an optimal temperature zone for prolonged sitting. In other words, it’s soft, breathable and comfortable. Wool is more expensive than synthetic alternatives, but its many positive properties justify its use in high quality seating.

Why Leather Upholstery

Why do we use only Full Grain Leather? Because it is the premium portion of a leather hide. Modern technology has created many new materials, but it still can’t produce a material that can outmatch the unique properties of natural leather. Natural leather is always the perfect temperature, an extremely breathable material, and it will adapt to your room and body temperature within 12 seconds, so the notion that leather is cold is a misconception. In addition, leather gives furniture a luxurious look and feel.

Leather is a surprisingly practical material. Leather furniture lasts, on average, four to five times as long as fabric furniture. Leather is more resilient, stronger and has long been synonymous with opulence. It provides comfort and class, is extremely durable and is easy to care for - just use a damp cloth to remove any dust. Leather softens and improves in texture, color and overall appearance with time, it gets better with age. As it ages, top-quality leather will develop a beautiful, lustrous patina (a soft sheen) that adds to its appearance and style. The use of leather in furniture not only gives it a very elegant, classy look, but it's also a look that endures. Leather has been used to cover sofas and chairs for centuries. We are committed to continuing that tradition.

We firmly believe that the best decision is an informed decision. We therefore believe in educating our customers in leather evaluation so they may avoid the pitfalls others make and to appreciate the quality of materials we use. By learning about leather processes, one may find that a high-grade leather sofa could cost up to 10 times the price of a similar but lower-quality piece, however leather is no longer financially out of reach. The hides we use at Classic Elegance, nearly perfect and mark-free, are rare and prized. We encourage you to closely examine our seating and form your own opinion on the overall quality, and therefore the value of our unique furniture.

Why do we use only Full Grain Leather? Because it is the premium portion of a leather hide. Modern technology has created many new materials, but it still can’t produce a material that can outmatch the unique properties of natural leather. Natural leather is always the perfect temperature, an extremely breathable material, and it will adapt to your room and body temperature within 12 seconds, so the notion that leather is cold is a misconception. In addition, leather gives furniture a luxurious look and feel.

Leather is a surprisingly practical material. Leather furniture lasts, on average, four to five times as long as fabric furniture. Leather is more resilient, stronger and has long been synonymous with opulence. It provides comfort and class, is extremely durable and is easy to care for - just use a damp cloth to remove any dust. Leather softens and improves in texture, color and overall appearance with time, it gets better with age. As it ages, top-quality leather will develop a beautiful, lustrous patina (a soft sheen) that adds to its appearance and style. The use of leather in furniture not only gives it a very elegant, classy look, but it's also a look that endures. Leather has been used to cover sofas and chairs for centuries. We are committed to continuing that tradition.

We firmly believe that the best decision is an informed decision. We therefore believe in educating our customers in leather evaluation so they may avoid the pitfalls others make and to appreciate the quality of materials we use. By learning about leather processes, one may find that a high-grade leather sofa could cost up to 10 times the price of a similar but lower-quality piece, however leather is no longer financially out of reach. The hides we use at Classic Elegance, nearly perfect and mark-free, are rare and prized. We encourage you to closely examine our seating and form your own opinion on the overall quality, and therefore the value of our unique furniture.

|

What is the difference between Top, Full, Corrected and Split Leather?

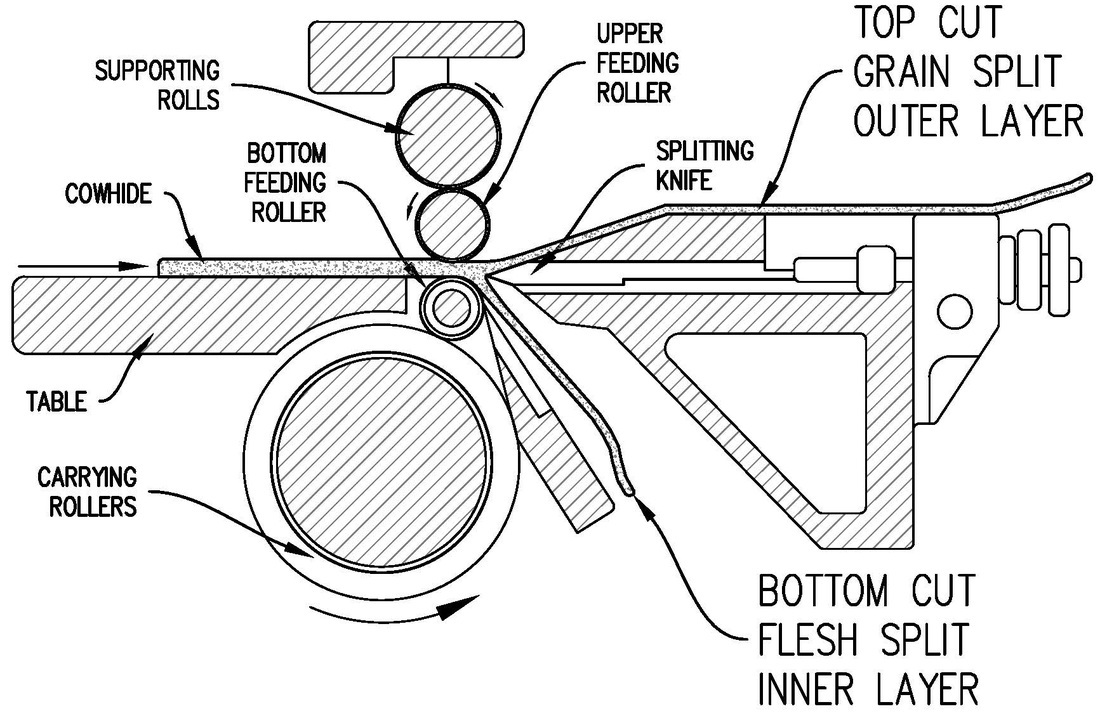

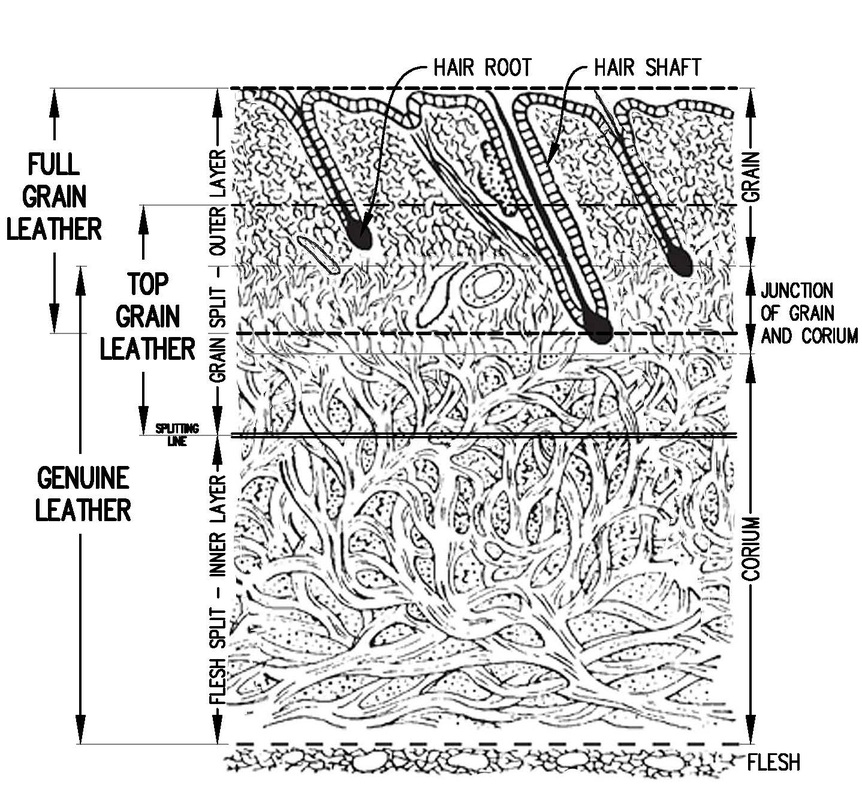

Once a cow’s skin is removed in one layer, the outer layer of skin is ‘split’ from the lower layers of skin. It is virtually shaved off. Figure 1 illustrates how a cowhide, which initially is very thick, is sliced into two layers - the Top Cut or Grain Split, and the Bottom Cut or Flesh Split. The important advantages of the Top Cut include more natural oils and larger pores, which facilitate a more breathable material. Full Grain has been casually equated with Top Grain in the sales environment, but they are not exactly the same (as we will explain). Top Grain Leather. Top Grain is a term that covers several layers of the hide but has also become a confusing general term to describe quality. The word 'top' indicates the 'top' portion of a hide, not really the quality of the leather. In other words, it indicates from where the leather was cut rather than the grade. Top Grain Leather can include the lower portion of the Full Grain split and share some of its characteristics to include the absence of corrections (See Figure 2). It can also require some correction because it is not entirely Full Grain. Also, in cases where the upper layer of the Bottom Cut is of sufficient quality (and although finished to add grain and remove defects as a Corrected Grain Leather) it too can be referred to as Top Grain. Ultimately, the physical properties of finished leather predominantly depend on the natural quality of the hide layer and the nature of its tanning. |

Full Grain Leather. Full grain leather is the outermost portion of the Top Cut of a cowhide and is the most valued part of the hide. We use only Full Grain Leather on our furniture. It is Top Cut Leather in which the grain or surface of the hide has not been altered in any way except for the removal of hair. It is also the strongest and most durable part of the hide, yet it is soft and supple and if properly cared for should last almost indefinitely. The grain remains, contributing to fiber strength and durability. The grain also has breathability, resulting in less moisture from prolonged contact. Natural markings on the skin such as scratches or stretch marks are visible, but are not excessive or unsightly and in fact, are considered the "signature of fine leather." Some people are surprised to learn that the absence of natural markings can often mean a lesser quality tanned leather hide. This is because poorer grade cowhides are often heavily sanded to remove these markings making the leather thinner. Scars or any other markings are not "defects" in the leather, but instead, genuine proof of its natural origin vs. hides that have fewer flaws. Only 10-15% of all hides can be finished as Full Grain Leather. Full Grain Leather also refers to hides that have not been sanded, buffed, or snuffed as opposed to any grain correction to remove imperfections on the surface of the hide. Rather than wearing out, Full Grain Leather will develop a patina during its expected useful lifetime. The highest quality leather seating is typically made from Full Grain Leather. See Figure 2.

Corrected Grain Leather. This could be Top Grain but is usually a Bottom Cut Leather layer that has been "corrected" through sanding away natural markings and major blemishes on the leather’s surface. Once the surface is uniform, it is typically embossed into a natural grain skin pattern or pebble grain pattern. The majority of modern upholstery leather is Corrected Grain. As previously mentioned, there are different grades of Corrected Grain Leather that depend on the degree of correction - the less corrected the better. However, there is no standard grade. Every tannery has its own method of grading. Most Corrected Grain Leather is used to make pigmented leather since a solid pigment helps hide the corrections and / or imperfections. The best Corrected Grain Leather (leather with minimal blemishes) can be obtained with a Semi-aniline finish. Some believe that Corrected Grain Leather is more durable than Full Grain Leather. This is subject to debate, since it depends on the reputation of the tanneries and their processes.

Split Leather. Split Leather is the Bottom Cut of the cow hide, virtually “split” from the epidermis or Top Cut. Split Leather has no skin features and could be sliced again into several more layers. Split Leather is weaker, thinner, cannot comfortably absorb moisture, but can be sanded down and embossed with a consistent graining pattern to be used for upholstery. Modern methods, which gradually became more refined and efficient, are designed to convert Split Leather into a product that looks and behaves similar to Top Grain Leather. However, finishing methods may improve the qualities of Split Leather only so far. Split Leather won’t stand the test of time in an active household, but as a lower grade is generally more affordable. Split Leathers are typically used on non-wear areas of furniture as on the outside back and sides of sofa for a slight cost savings in order to achieve certain desired price points. Even though Split Leather provides an attractive finished product at a lower cost than a Top Grain Leather, reputable furniture makers do not use Split Leather for upholstery at all. Although a sales tag or product label may state "made with Full Grain or Top Grain or Genuine Leather," that doesn't mean the entire sofa or chair is made from this specific type of leather. It may be just the seat and armrests are covered with Top Grain, and the back and sides are covered with Split Leather.

Split Leather. Split Leather is the Bottom Cut of the cow hide, virtually “split” from the epidermis or Top Cut. Split Leather has no skin features and could be sliced again into several more layers. Split Leather is weaker, thinner, cannot comfortably absorb moisture, but can be sanded down and embossed with a consistent graining pattern to be used for upholstery. Modern methods, which gradually became more refined and efficient, are designed to convert Split Leather into a product that looks and behaves similar to Top Grain Leather. However, finishing methods may improve the qualities of Split Leather only so far. Split Leather won’t stand the test of time in an active household, but as a lower grade is generally more affordable. Split Leathers are typically used on non-wear areas of furniture as on the outside back and sides of sofa for a slight cost savings in order to achieve certain desired price points. Even though Split Leather provides an attractive finished product at a lower cost than a Top Grain Leather, reputable furniture makers do not use Split Leather for upholstery at all. Although a sales tag or product label may state "made with Full Grain or Top Grain or Genuine Leather," that doesn't mean the entire sofa or chair is made from this specific type of leather. It may be just the seat and armrests are covered with Top Grain, and the back and sides are covered with Split Leather.

Leather Finishes. Full Grain Leathers are normally available in two finish types which depend on physical properties and the desired level of leather protection: Aniline and Semi-aniline. Aniline finishing introduces soluble dye to color the leather and leaves the surface in its original condition. Semi-Aniline finishing includes a surface protectant in the dying process. At Classic Elegance, we currently use premium Full Grain Leather for all leather surfaces, with both Aniline and Semi-Aniline finish types, but primarily use Hand-Rubbed Semi-Aniline Leather because of its protective properties. Hand-Rubbing a Semi-Aniline finish allows greater control of the dying process. For appropriate seating pieces, we favor leather finished in the Sauvage technique which features rubbing layers of two or more colors of aniline dye into Full Grain Leather until the desired color tones are achieved. This process is done by skilled artisans who understand the interplay of colors where a patina of multiple rich tones is desired. Because the cow hide is Full Grain, subtle natural markings such as healed scares, scratches, insect bites and brands can be present. Hand Rubbed Leather is highly desired for heirloom furniture, antiques and high-end leather furnishings. We obtain our leathers from only reputable commercial providers.

At present, leather that is processed from ‘splits’ or other manmade materials are known by several names: split leather, corrected leather, embossed leather, coated leather, Suede, Napa leather, painted leather, or reconstituted leather. Many mass-producers use these types of leather at a fraction of the cost of genuine Top Grain Leather. Some manufacturers are using a combination of Split Leather and Top Grain leathers because it helps reduce the price of furniture, without greatly reducing the relative quality.

By contrast, at Classic Elegance, we use only premium Full Grain Leather on all surfaces. Notably, we do not join smaller pieces together which eliminates any seams on our leather surfaces. Leather is a natural product and the size of cowhides can be very different depending on an animal's age and breed. Our exposed seating surfaces are covered only with the ‘bend’ portion, the premium area of the hide. Parts such as the belly, shanks, and flanks are generally not used because they have a higher stretching factor as well as noticeable differences in texture. Also, each hide has different markings on it that reflect the animal’s life history to include scars from barbed-wire cuts and insect bites, brands, stretch marks from the birthing process, random or spine holes, and gouges or breaks in the finish after tanning. Because of these limiting factors, we can generally only use between 20% and 60% of each hide for a project. Finally, we carefully attach each leather covering with hand-driven matching brass nails, chosen to compliment the tones and style of the subject piece.

At present, leather that is processed from ‘splits’ or other manmade materials are known by several names: split leather, corrected leather, embossed leather, coated leather, Suede, Napa leather, painted leather, or reconstituted leather. Many mass-producers use these types of leather at a fraction of the cost of genuine Top Grain Leather. Some manufacturers are using a combination of Split Leather and Top Grain leathers because it helps reduce the price of furniture, without greatly reducing the relative quality.

By contrast, at Classic Elegance, we use only premium Full Grain Leather on all surfaces. Notably, we do not join smaller pieces together which eliminates any seams on our leather surfaces. Leather is a natural product and the size of cowhides can be very different depending on an animal's age and breed. Our exposed seating surfaces are covered only with the ‘bend’ portion, the premium area of the hide. Parts such as the belly, shanks, and flanks are generally not used because they have a higher stretching factor as well as noticeable differences in texture. Also, each hide has different markings on it that reflect the animal’s life history to include scars from barbed-wire cuts and insect bites, brands, stretch marks from the birthing process, random or spine holes, and gouges or breaks in the finish after tanning. Because of these limiting factors, we can generally only use between 20% and 60% of each hide for a project. Finally, we carefully attach each leather covering with hand-driven matching brass nails, chosen to compliment the tones and style of the subject piece.

Finished Product

At Classic Elegance, we have chosen to specialize in the creation and restoration of unique, high-quality furniture pieces rather than mass production because we believe in heirloom furniture of exceptional quality. We use only the best hardwoods, craftsmanship, finishing products and techniques. We use only premium Top Full Grain Leather to cover all our upholstered surfaces because we find this particular leather has the perfect balance of quality, style, durability and feel. Sit, relax, and enjoy the difference that Classic Elegance builds into each and every piece. Thank You!

At Classic Elegance, we have chosen to specialize in the creation and restoration of unique, high-quality furniture pieces rather than mass production because we believe in heirloom furniture of exceptional quality. We use only the best hardwoods, craftsmanship, finishing products and techniques. We use only premium Top Full Grain Leather to cover all our upholstered surfaces because we find this particular leather has the perfect balance of quality, style, durability and feel. Sit, relax, and enjoy the difference that Classic Elegance builds into each and every piece. Thank You!